Connector Pin, Copper Pin, PIN, Insert Core

Product Name: Connector Pin, Copper Pin, PIN, Insert Core

English Name: Connector Pin

Material: Brass (C3604, H62, etc.)

Process: Turning, Machining

Production Equipment: Swiss-type CNC Lathe, Automatic Lathe

Surface Treatment: Tin Plating, Gold Plating, Silver Plating, etc.

Application Fields: Connectors, PCBs, Electronic Components

Description:

Connector pins, also referred to as copper pins, PINs, or insert cores, are essential components in electronic systems. They are made from high-quality brass materials such as C3604 and H62, ensuring excellent conductivity and durability. These products are manufactured using advanced machining processes, including precision turning and CNC machining, with the help of state-of-the-art equipment like Swiss-type CNC lathes and automatic lathes.

To enhance performance and reliability, the pins undergo surface treatments such as tin plating, gold plating, or silver plating, tailored to meet specific application requirements. Widely used in connectors, PCBs, and other electronic components, these pins are critical for ensuring stable electrical connections in various industries.

PINs and connector pins are conductive components used for connecting electronic devices or circuit boards. They feature a plug-in design on one end, allowing them to be easily inserted into corresponding slots or interfaces. This facilitates the connection and communication between circuit boards, ensuring the proper functioning of devices.

PINs are widely used across various applications, including electronic components, connectors, transformers, inductors, electronic switches, modular power supplies, renewable energy systems, aerospace accessories, and medical equipment. They play a critical role in electronic device manufacturing, connectors, and PCBs, serving as essential components in the design and assembly of electrical and electronic systems.

The shape and size of connector pins are selected based on the design and requirements of the connector to ensure proper insertion into the connector socket and a stable connection.

Materials Used for Connector Pins:

Brass: C3604, H59, H62

Phosphor Bronze: C54400

Surface Treatments for Pins:

Gold plating

Bright tin plating

Matte tin plating

Silver plating

Production Range for PINs:

The production range is flexible and unrestricted. Currently, automatic feeding machines can handle materials with a minimum diameter of 0.5mm.

The quality and stability of connector pins are critical to the performance and reliability of equipment. As a professional manufacturer equipped with advanced production facilities and a skilled technical team, we specialize in the customization of PINs and connector pins in various specifications and models to meet customer requirements. We are committed to providing high-quality, reliable products along with professional services and solutions to fulfill diverse connection needs.

Examples of Pin Products:

|

Cross PIN, Made of Copper with Gold Plating The cross PIN is one of the simplest types of PINs. It is commonly used for PCB solder terminal positioning and provides connections between electronic devices, enabling the transmission of electrical signals and power signals between circuit boards. Cross PINs are designed to offer reliable connection performance, capable of handling specific levels of current and voltage, ensuring stable connections and proper operation of devices. In electronic device manufacturing, the cross PIN is a widely used type of connector. FULLERKREG Precision offers significant production advantages, high-quality control standards, and competitive cost benefits. |

|

Knurled Pin The knurled pin is a common type of connector pin, designed with a textured surface to improve grip and facilitate easier handling during installation. Pins and inserts play a critical role in the design and functionality of electronic devices. Their high level of standardization and wide availability make the design, manufacturing, and maintenance of electronic equipment more efficient and convenient. As technology continues to advance, the design of connectors evolves to meet increasing performance demands and diverse application requirements. |

|

Pins and Cross-Shaped Copper Pins Pins and sockets used in connectors are essential components in electronic engineering. They play a critical role in transmitting current or signals on printed circuit boards (PCBs) or between devices. The design of pins (male connectors) and sockets (female connectors) aims to ensure that electronic devices can be connected and disconnected safely, reliably, and conveniently. Pins typically refer to protruding conductive components that can be inserted into a corresponding part, while sockets are the complementary parts designed to receive the pins. This design allows for tight, reversible connections between electronic devices or their components, enabling multiple connections and disconnections without damaging the equipment. |

|

Connector Pin, PIN Material: Brass C3604 (Raw finish, ready for plating) |

|

Silver-Plated Pin |

|

Silver-Plated Pin |

|

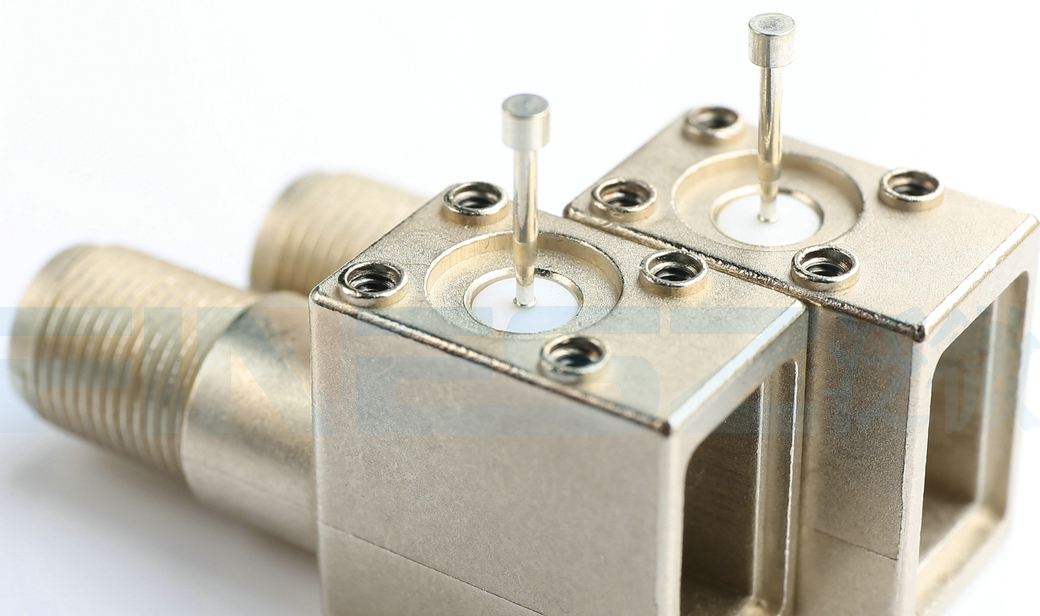

Connector PIN, Multi-Step Pin with Chamfers and Tin Plating The connector PIN is a multi-step, chamfered pin with a tin-plated surface. After insertion into the insulator, it is assembled into the connector (see attached diagram). |

Pin Application Scenarios:

Pin Processing Examples:

Materials and Surface Treatments for Connector Pins (PINs)

Connector pins and pin cores are typically machined from copper rods or elastic copper rods with excellent electrical conductivity. To achieve low contact resistance and corrosion resistance, the surface is treated with gold plating, silver plating, or tin plating.

Commonly Used Materials:

Brass and Copper Alloys:

C3604, C3602, H59, Hpb59-1, Hpb59-3, H62, H65, H68, H70, H80

Phosphor Bronze and Other Copper Alloys:

C5400, C2700, C2680, C5210, C5191, C51000, QBe2.0, C1100

The raw materials are commonly supplied as 2.5-meter-long rods for machining.

Material Characteristics:

H59 Series and C3604:

Cost-effective options with high strength and hardness.

Excellent plasticity, even under high-temperature conditions, allowing for effective pressure processing.

Moderate corrosion resistance, making them ideal for pin manufacturing.

H62 Brass:

Average copper content: 62%.

Good mechanical properties with excellent plasticity in hot conditions and adequate plasticity in cold conditions.

Easy to machine and weld, suitable for applications requiring higher loads (compared to H59 series and C3604).

Similarly, H65, H68, H70, and other high-copper-content alloys can also be used for pin and socket components.

C54400 Phosphor Bronze (with Lead):

Good machinability and cold workability.

Easy to weld and braze.

Often used for manufacturing pins and sockets.

C2700, C2680, C1100, and Similar Materials:

These materials exhibit similar properties and are also commonly used for pin and socket manufacturing.

Surface Plating for Pins (PINs)

The plating on connector pins not only enhances their durability and wear resistance but also helps establish and maintain stable impedance from an electrical performance perspective. Common plating options include:

Tin Plating:

Typically applied as a tin layer over a nickel base. Tin-plated pins exhibit excellent solderability and conductivity.

Gold Plating:

Leveraging gold's superior conductivity, gold plating reduces resistance and improves electrical performance. Additionally, it provides a premium and attractive appearance.

Silver Plating:

Similar to gold plating, silver plating offers excellent conductivity while maintaining a balance of cost and performance.

Nickel Plating:

Due to its lower cost, nickel plating is also widely used for pin and socket components.

|

Sales Direct United States Sales +86 159 5016 9967 |

Sorry, there are no products matching your search.